motor control center components in industrial and commercial settings, serving as the nerve center for managing and regulating the operation of electric motors. These panels provide a centralized interface for operators to control, monitor, and protect various motors within a facility, ensuring efficient and safe functioning of machinery and processes.

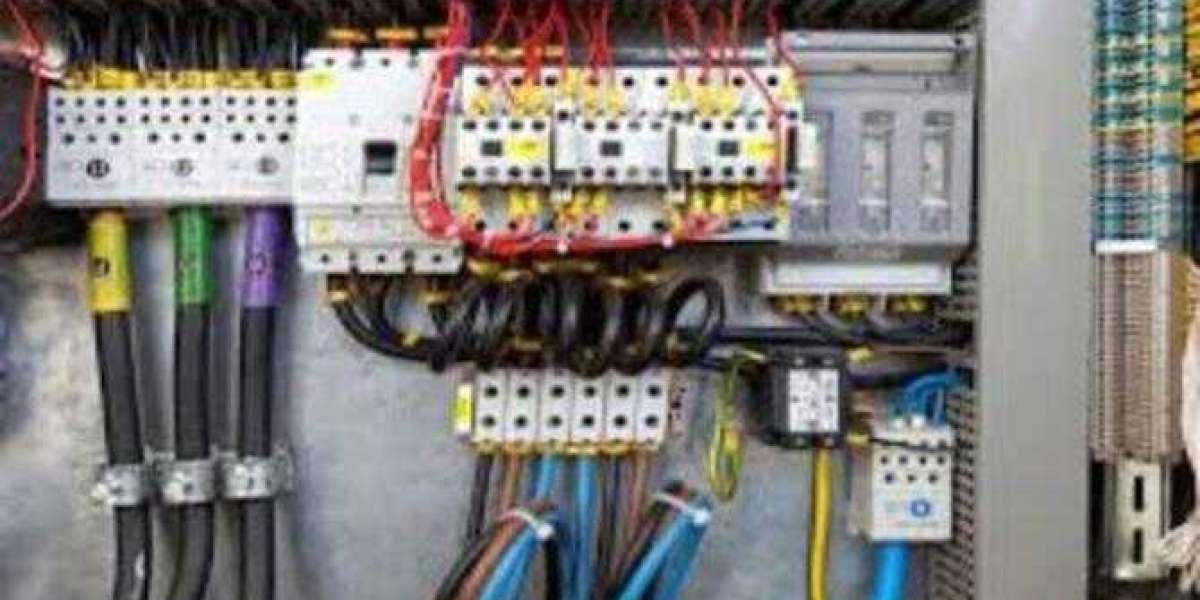

At their core, motor control panels consist of a combination of electrical devices, such as motor starters, circuit breakers, relays, and switches, all strategically arranged to facilitate smooth motor operation. The primary objective is to enable seamless motor startup, speed control, direction changes, and shutdown procedures. This is crucial for maintaining production processes, optimizing energy consumption, and preventing abrupt equipment wear and tear.

One of the key features of motor control panels is the inclusion of variable frequency drives (VFDs) or soft starters. These technologies allow for precise control of motor speed, reducing energy spikes during startup and enabling gradual acceleration. As a result, VFDs and soft starters contribute to extending motor lifespan, minimizing stress on mechanical components, and reducing the overall maintenance requirements.

Safety is of paramount importance in motor control panels, and modern designs incorporate an array of protective devices. Overload relays, thermal sensors, and short-circuit protection mechanisms are integrated to safeguard motors from damage due to excessive current or overheating. In the event of a fault, these protections automatically interrupt the circuit, preventing potential hazards and enhancing operational reliability.

In recent years, motor control panels have evolved with advancements in automation and connectivity. Integration with supervisory control and data acquisition (SCADA) systems enables remote monitoring, diagnostics, and adjustments. This not only enhances operational efficiency but also facilitates predictive maintenance, as operators can identify and address potential issues before they escalate.

Furthermore, motor control panels are designed to accommodate a variety of motor types and sizes, catering to the diverse needs of different industries. Whether it's a small motor powering a conveyor belt or a large motor driving a production line, these panels offer scalability and adaptability.

In conclusion, motor control panels play a vital role in modern industrial and commercial settings by providing centralized control, protection, and monitoring of electric motors. Their sophisticated design, encompassing motor starters, protective devices, and advanced technologies like VFDs, ensures optimal motor performance, energy efficiency, and operational safety. As industries continue to embrace automation and digitalization, motor control panels are poised to evolve further, contributing to enhanced productivity and sustainability across various sectors.